Characteristics

- Adhesive properties

- Surface modification properties

- Water and oil resistance

- Transparency and colorability

- Safety and environmentally friendly

- Easy to process

- Broad lineup

Adhesive properties

CHEMIPEARL™ can be coated and dried on various substrate materials such as paper, metal foils, and resin films to provide excellent heat-sealing properties. It also functions as a binder when added to water-based paints.

These CHEMIPEARL™ coatings are transparent and odorless, and can adjust for moisture and gas permeability.

In particular, XSP589 adheres well to a variety of substrates.

Main applications

Heat Seal Coatings for paper, film and aluminum packaging (food, medical, etc.)

Electrode binder, etc.

Recommended grades: S,V,XSP

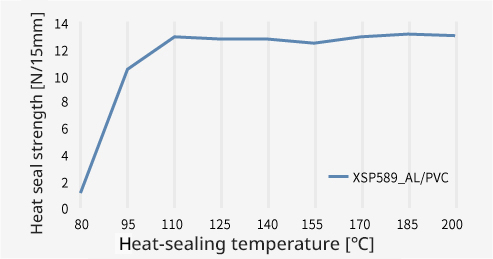

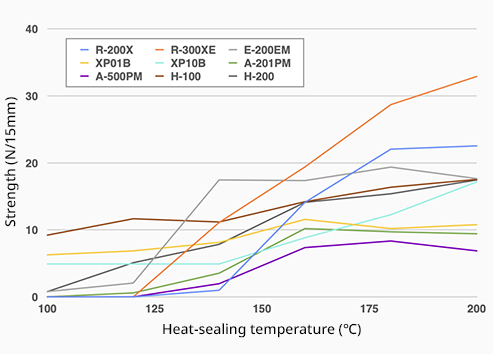

Dependence of adhesive strength of CHEMIPEARL™ coated aluminum foil on heat-sealing temperature

Peel strength can be adjusted according to heat-sealing conditions. Some grades have excellent heat sealing properties at low temperatures below 100℃.

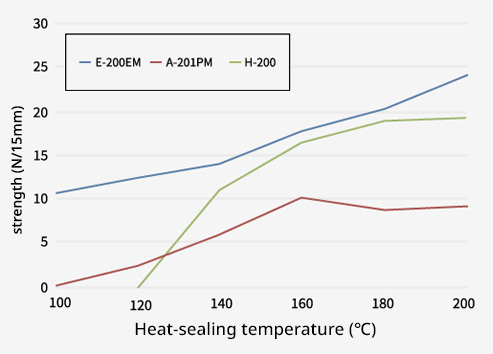

Heat-sealing performance of CHEMIPEARL™ coated aluminium foil against polyvinyl chloride (PVC)

We offer a lineup of grades that exhibit good heat-sealing performance even on polyvinyl chloride substrates, which are considered difficult to bond to.

Heat seal strength of CHEMIPEARL™ coated paper

In both cases, the adhesion was strong enough to destroy the substrate, demonstrating that the heat-sealing of CHEMIPEARL™ coated paper has sufficient strength.

| Peel strength [gf/15mm] | Peel mode | |

|---|---|---|

| S300 coated paper | 376 | Substrate material destroyed |

| S500 coated paper | 500 | Substrate material destroyed |

| V200 coated paper | 620 | Substrate material destroyed |

Substrate: 200g/m² base paper

Coating amount: 4–5 g/m² (6–7 g/m² for V200 only)

Drying: 120°C x 30 sec (150°C x 60 sec for V200 only)

HS: coating, 200°C x 0.2 MPa x 1 sec

Peeling: 180℃C peeling, 200 mm/min, 24 hours after HS

Surface modification properties

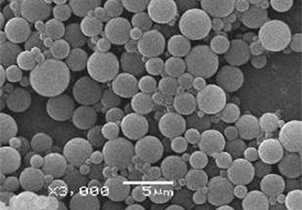

CHEMIPEARL™ is a polyolefin particulate dispersion with spherical particles and a narrow particle size distribution.

Dispersing CHEMIPEARL™ particles in coating films and fibers can dramatically increase abrasion resistance, slipperiness, and anti-blocking properties.

Main applications

Anti-abrasing agent and lubricants for water-based inks and paints.

Film anti-blocking agents, mold release agents, etc.

Fiber lubricants, etc.

Recommended grades: A,M,V,W

-

SEM image of CHEMIPEARL™

A product design that aligns the shape and particle size of dispersed particles enables significant surface modification with the addition of small amounts.

-

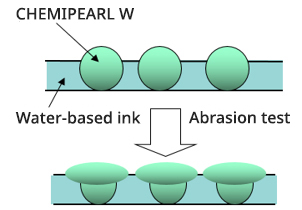

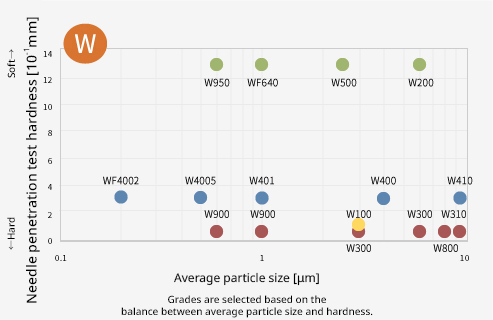

CHEMIPEARL™ W Series: mechanism of anti-abrasion

By selecting the appropriate grade according to the thickness of the printing layer and the microstructure of the paper surface, CHEMIPEARL™ particles protect the ink from abrasion.

-

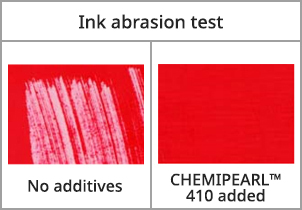

CHEMIPEARL™ W Series abrasion test

The printed surface of ink with CHEMIPEARL™ added exhibits dramatically improved anti-abrasion property compared to that of ink without CHEMIPEARL™.

Water and oil resistance

The coating film formed by coating and drying with CHEMIPEARL™ exhibits excellent water and oil resistance, derived from the chemical properties of the raw material polyolefin, and contributes to improving the chemical stability of the substrate surface.

It can be used not only as a stand-alone coating, but can also be added to water-based paints.

Results of water and oil resistance assessment for CHEMIPEARL™ coated paper

Water and oil resistance exceeding the values in the table can be expected by optimizing conditions for film deposition and selecting the ideal grade.

| Grade | Coating amount [g/m2] | Cobb300 value [g/m2] | KIT value [-] |

|---|---|---|---|

| S300 | 4.3 | 0.5 | 7 |

| S500 | 4.7 | 0.2 | 12 |

Main applications

Provides water and oil resistance to packaging materials, paper containers, and films, etc.

Recommended grades: S

Transparency and colorability

The coating film formed by coating and drying with CHEMIPEARL™ is colorless and highly transparent.

Heat-sealing properties can be added without damaging the original appearance of the substrate material.

It is also possible to add any color by blending coloring agents.

*only S100 and XSP589 are transparent.

Main applications

Maintains the design of the printed surface

Coloration of heat-seal surface

Recommended grades: S,XSP

CHEMIPEARL™ colored paint film

By blending colorants, the color of the coating film can be adjusted as desired and used for product design.

Transparency of CHEMIPEARL™ coating

For grades that transmit almost all visible light, the color and design of the substrate material are not compromised even after coating with CHEMIPEARL™.

Safety and environmentally friendly

CHEMIPEARL™ is an aqueous dispersion of fine polyolefin particles.

In principle, it contains no surfactants, organic solvents, or halogen compounds, making it an easy-to-handle product that is friendly to both the working environment and the global environment.

The raw material polyolefin resin itself is also safe, and can be used for applications where it is in direct contact with food products.

We offer a lineup of grades that comply with food laws and regulations.

*Please contact a representative to inquire about the status of inclusion in specific laws and regulations.

*Click here for Food Regulation Listing Status.

Main applications

Heat seal coatings for paper, film and aluminum packaging (food, medical, etc.)

Anti-abrasing agent and lubricants for water-based inks and paints.

Film anti-blocking agents, mould release agents, etc.

Fiber lubricants, etc.

Recommended grades: W,S,V,M,A,XSP

Easy to process

CHEMIPEARL™ can be used alone or blended easily with other agents, because it is a liquid product.

It can be used for products in various forms, such as film, pellet, and fiber.

Especially for coating, it has a proven track record with many coating machines and in a wide range of usage scenarios.

Main applications

Coating on substrates (gravure coating, roll coating, spray coating, etc.)

Additive for paints and coatings

Fiber immersion / soaking

Recommended grades: S,V,M,A,XSP

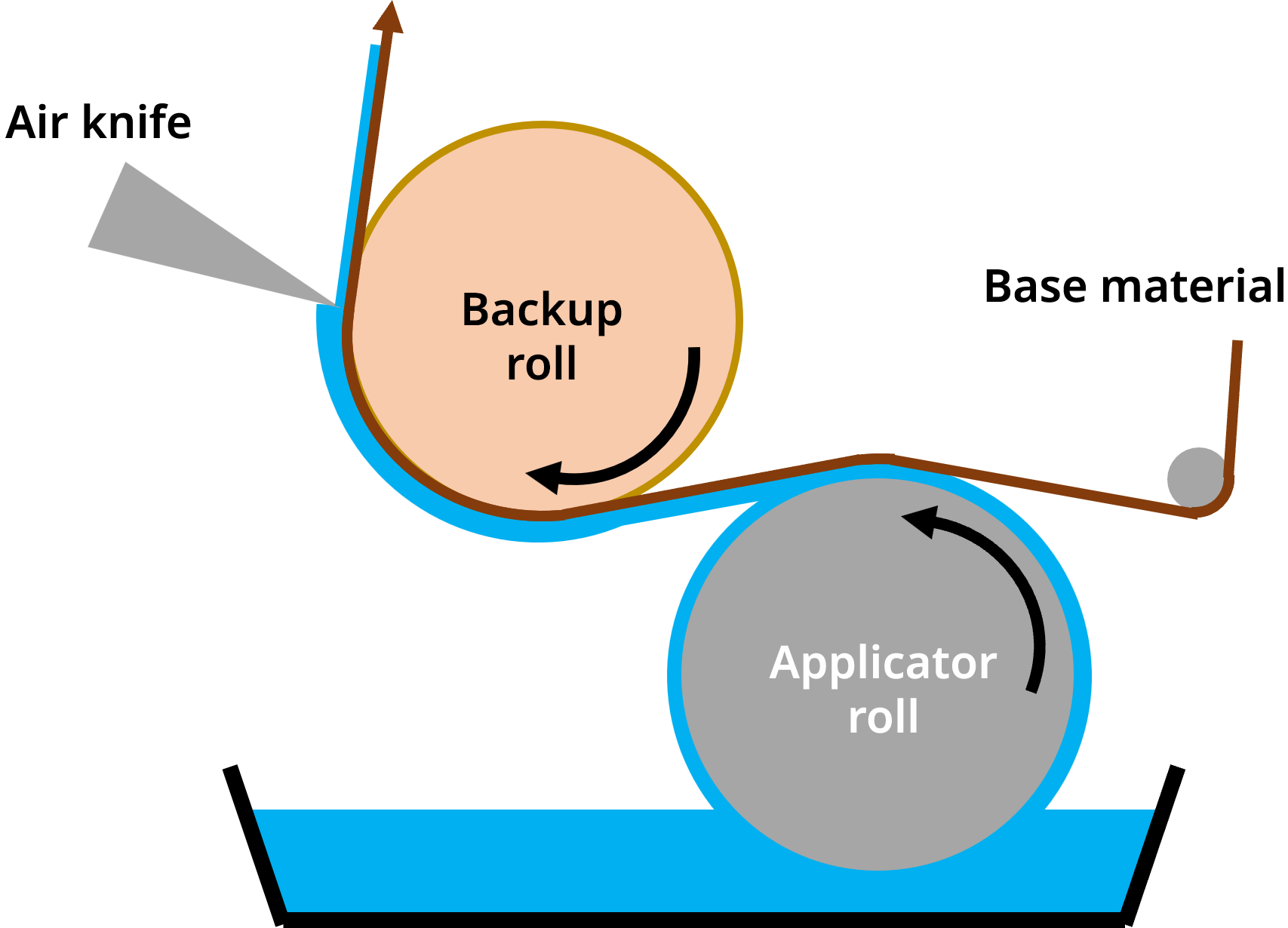

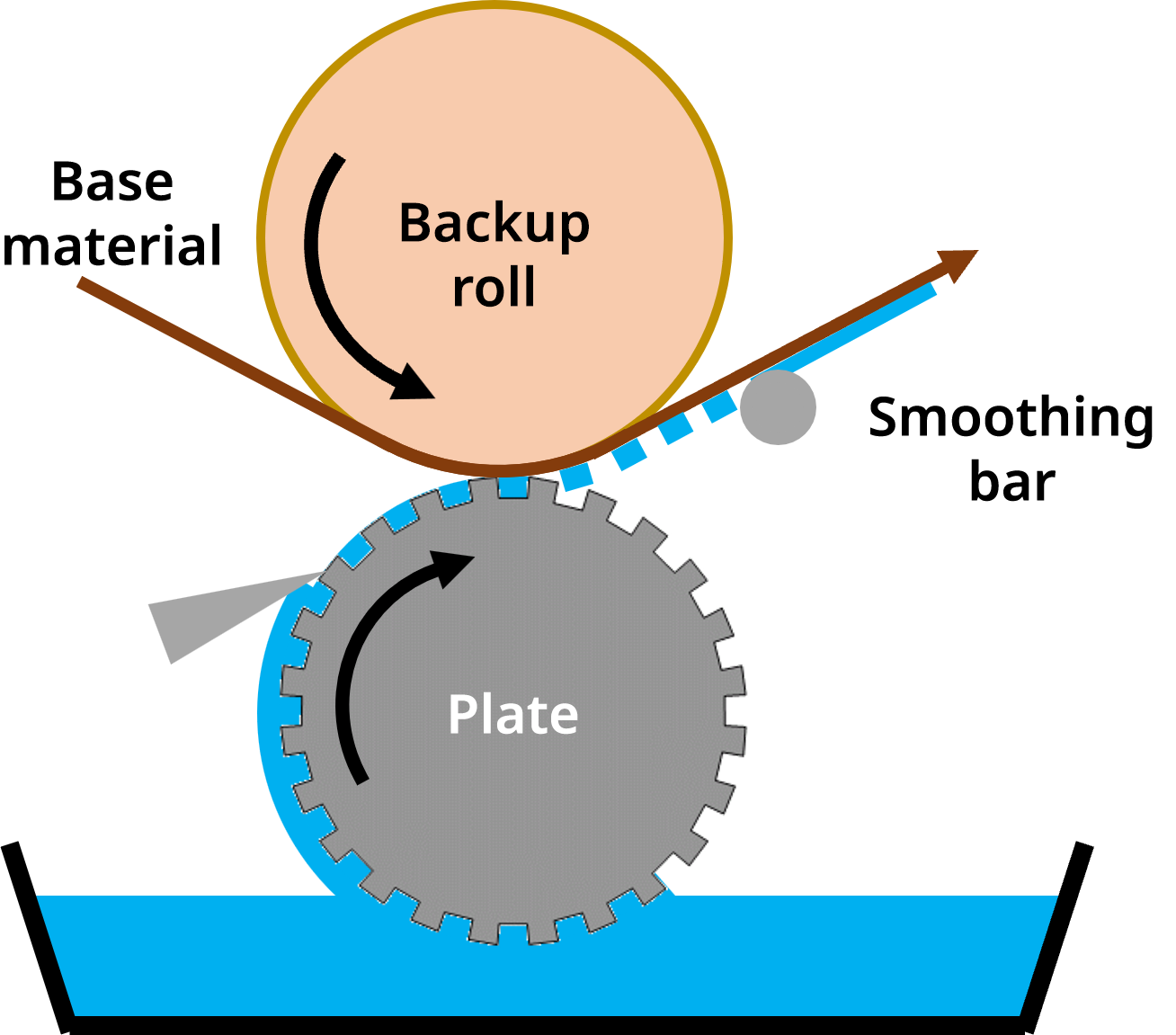

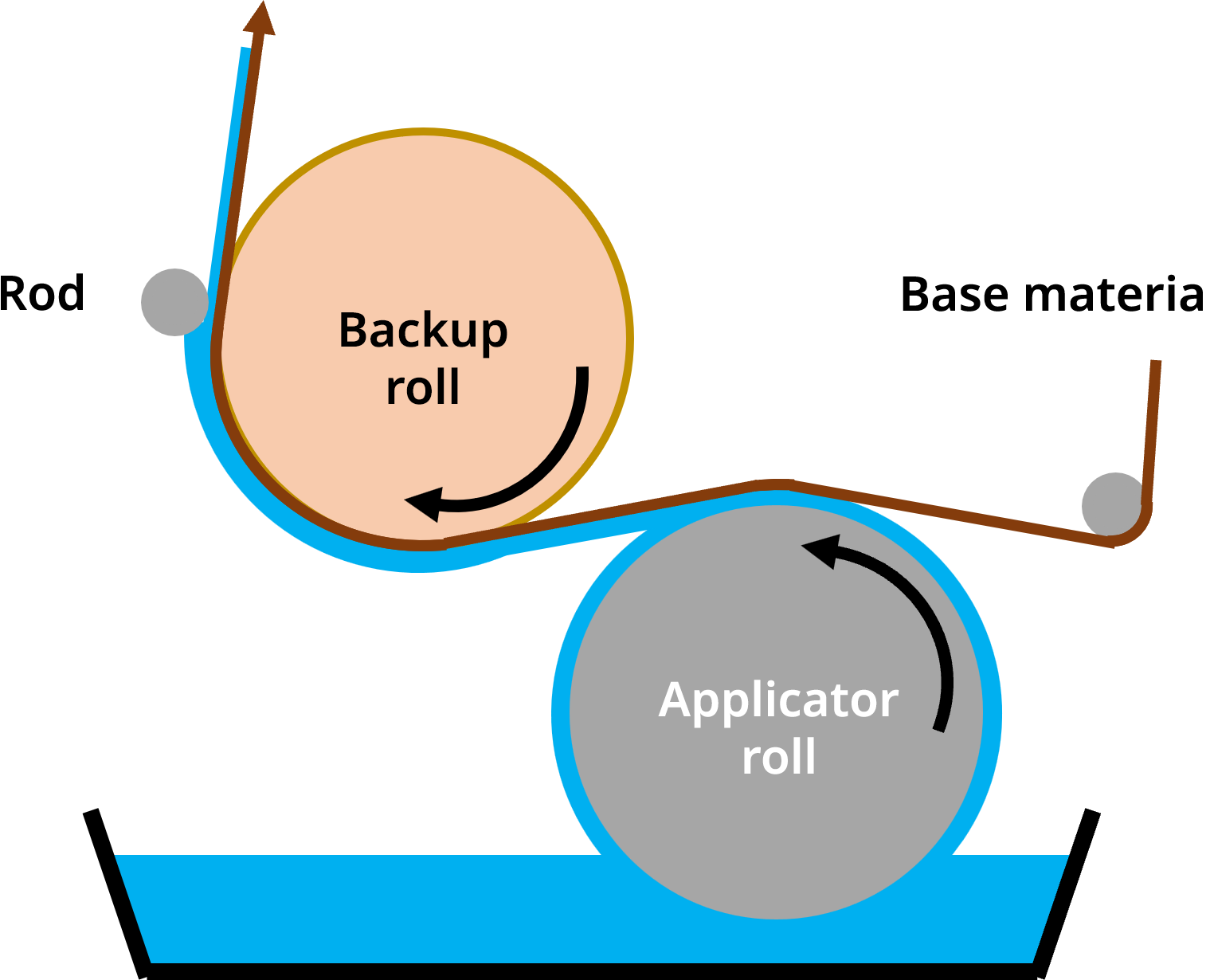

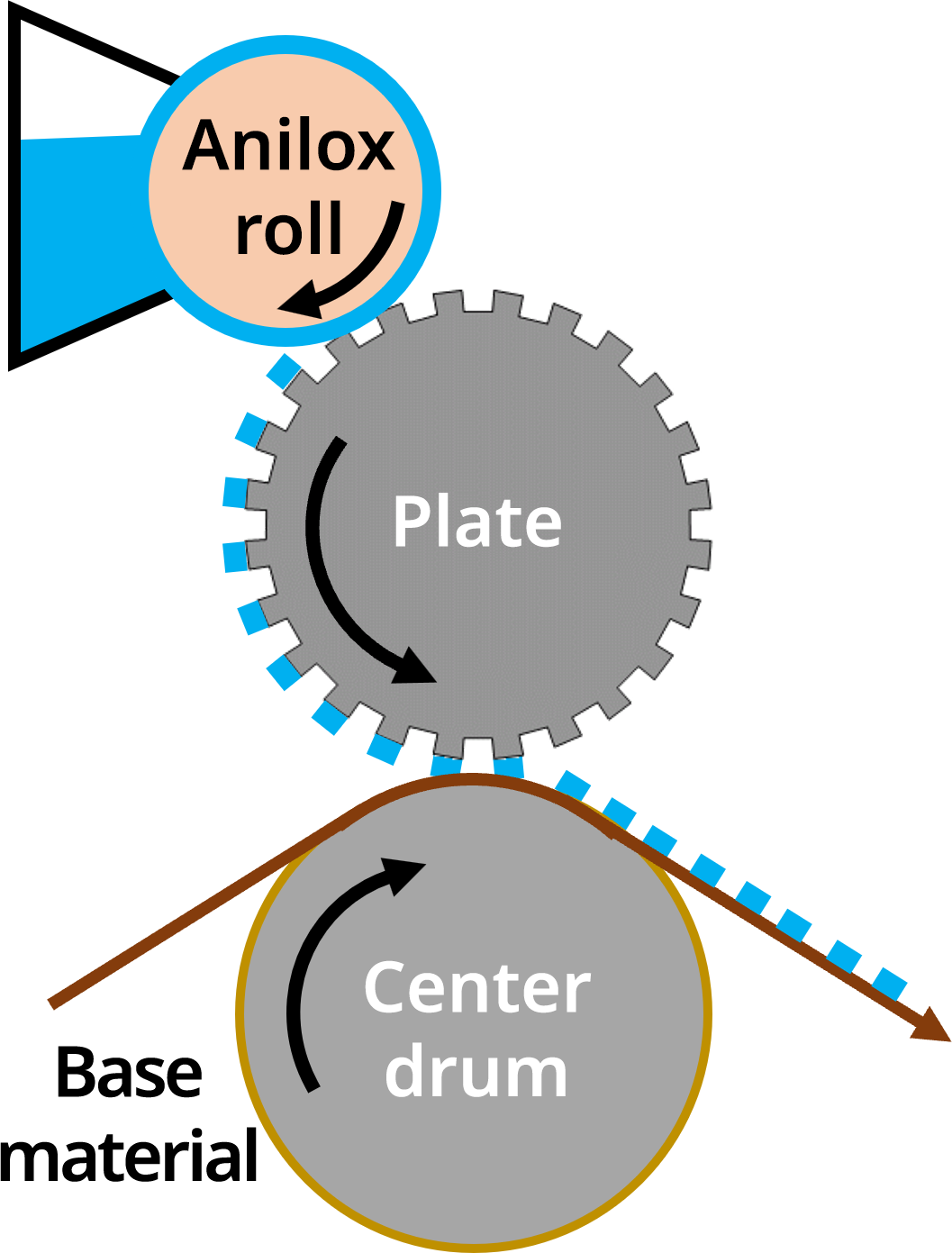

Illustrations of recommended coating machines

CHEMIPEARL™ has an extensive track record of use by many customers and can be used on a wide variety of coating machines, and under a wide variety of coating conditions.

-

Air knife coater

-

Gravure coater

-

Rod coater

-

Flexographic printing press

-

Curtain coater

Broad lineup

CHEMIPEARL™ offers a wide variety of more than 35 grades in five series.

In order to meet the needs for characteristics not found in our existing main lineup of grades, we are also developing several more grades as developmental products.

Since various functionality can be added by a variety of grades, we can recommend grades and methods that should be used according to a wide range of needs and usage scenarios.

CHEMIPEARL™ W Series lineup

- Adhesive properties

- Water and chemical resistance

- Dielectric properties

- Compliance with food laws and regulations

- Stretchability (extensibility)

- Liquid repellency

- Transparency

Adhesive properties

Excellent adhesion between non-polar materials (polyolefin, etc.) and polar materials (metal, nylon, etc.).

Click here for a substrate compatibility chart.

Main applications

Heat sealing materials

Dry laminate adhesives

Primers

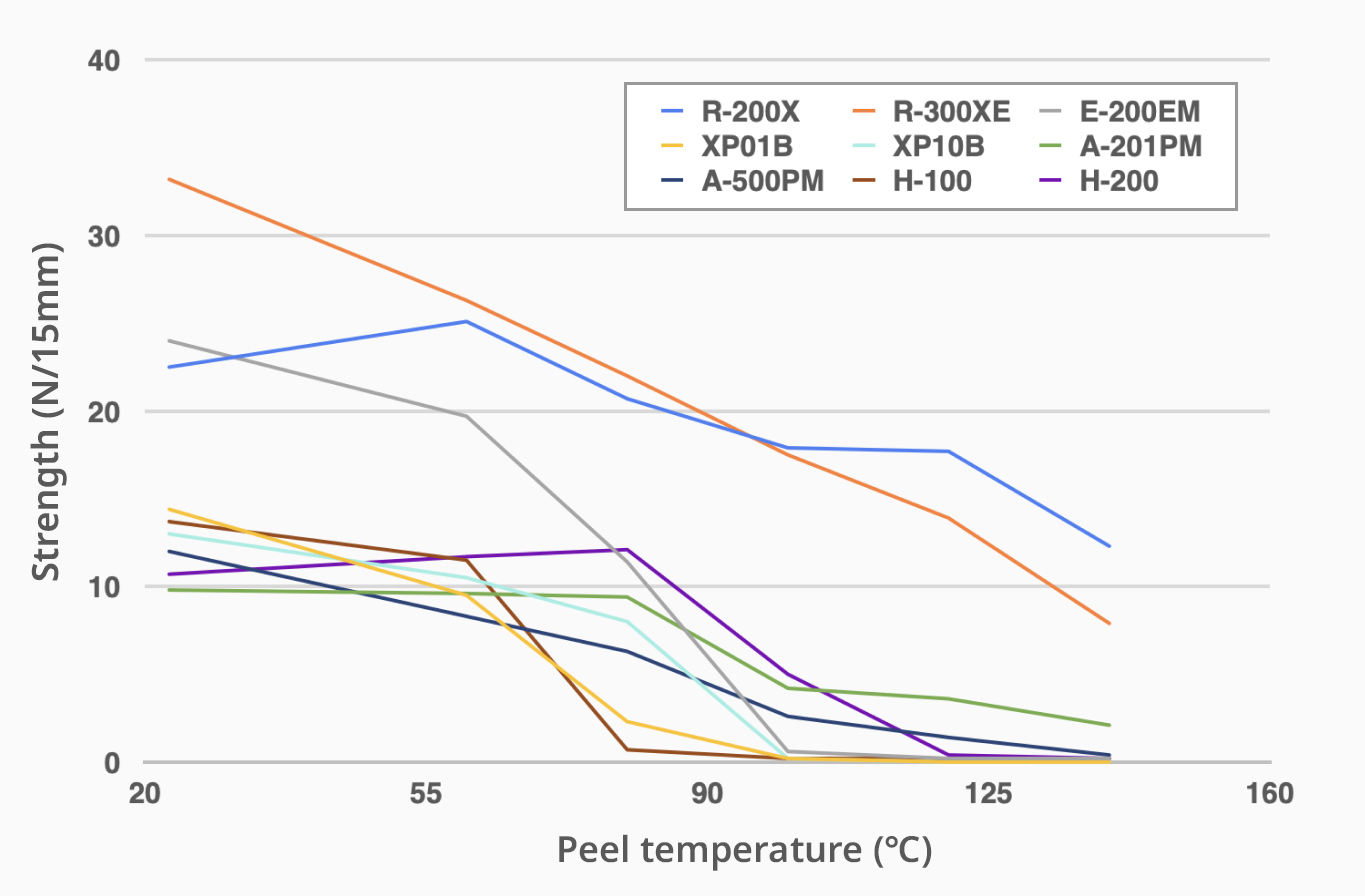

AL/PP heat sealing strength

UNISTOLE™ is applied as a coating on soft aluminum and dried.

(Drying conditions: R Series: 200℃ for 20 seconds, other grades: 120℃ for 60 seconds. Dry film thickness: 5 μm.)

Thermo-compression bonded to PP at 0.2 MPa for 1 second. Peel test at room temperature, 180℃, 100mm/min.

AL/PE heat sealing strength

UNISTOLE™ is applied as a coating on soft aluminum and dried.

(Drying conditions: 150℃ for 60 seconds. Dry film thickness: 3 μm.)

Thermo-compression bonded to PE at 0.3 MPa for 1 second.

Peel test at room temperature, 180℃, 100mm/min.

Heat-resistant adhesive strength

UNISTOLE™ is applied as a coating on soft aluminum and dried.

(Drying conditions: R Series: 200℃ for 20 seconds, other grades: 120℃ for 60 seconds. Dry film thickness: 3 μm.)

Coated surfaces are thermo-compressed together at 0.3 MPa and 200℃ for 1 second. Peeling test at prescribed temperature, 180℃, 50mm/min.

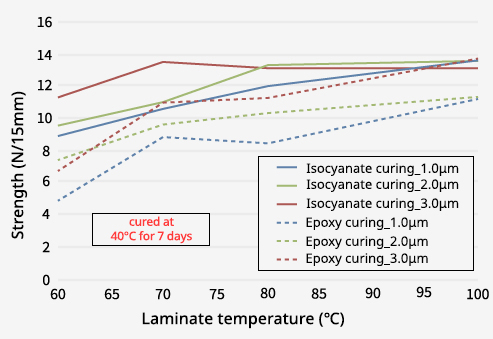

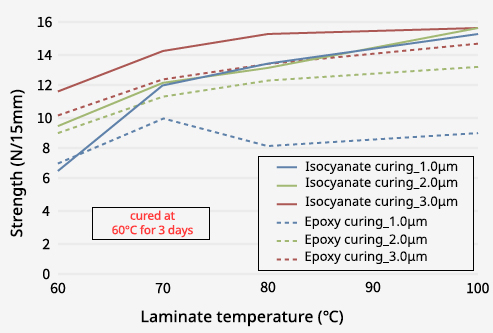

Strength when hardener is added

UNISTOLE™ is applied as a coating on soft aluminum and dried.(Drying conditions: 120℃ for 30 seconds.)

(Drying conditions: 120℃ for 30 seconds.)

Laminated with CPP at the prescribed temperature and cured at 60℃ for 3 days.

Peel test at room temperature, 180℃, 50mm/min.

*Please inquire separately about hardener.

Water and chemical resistance

UNISTOLE™ is composed mainly of polyolefins, making it stable against aqueous solutions and solvents, with excellent water and chemical resistance.

Main applications

Dry laminate adhesives for Lib (lithium-ion battery) pouches

Primer for cosmetic bottles

Primer for automotive interiors

Primer for electrical materials and electronic components

Recommended grades: P,XP

P Series (P-601) resistance table

| Finish coat | Appearance assessment | Adhesion assessment | |

|---|---|---|---|

| Initial adhesion | Acrylic | - | ◎ |

| PVC | - | ◎ | |

| Heat resistance 80℃, 400h |

Acrylic | No change | ◎ |

| PVC | No change | ◎ | |

| Water resistance 80℃, 24h |

Acrylic | No change | ◎ |

| PVC | No change | ◎ | |

| Alcohol resistance 50%EtOH 40℃, 24h |

Acrylic | No change | - |

| PVC | No change | - | |

| Chemical resistance Neutrogena 80℃, 24h |

Acrylic | No change | ◎ |

| PVC | No change | ◎ |

Electrolyte resistance

| Isocyanate curing | Epoxy curing | |

|---|---|---|

| Normal mode strength | ◎ | ○ |

| Electrolyte resistance | ○ | ◎ |

UNISTOLE™ is applied as a coating on soft aluminium and dried.

(Drying conditions: 120℃ for 60 seconds. Dry film thickness: 4 μm.)

Hand-laminated with CPP at the prescribed temperature and cured at 60℃ for 3 days. Peel test at room temperature, 180℃, 50mm/min.

Electrolyte resistance assessed at 1 MLiPF6 EC/DEC (=3/7) + 1000 ppm water for 7 days at 85℃. Rating: 0: 8–14 N/15mm, ◎: 14 N/15mm or more

Dielectric properties

UNISTOLE™ has a lower relative permittivity (dielectric constant) than general adhesives and lower dependence on frequency.

Main applications

Adhesives for electrical materials and electronic components

Adhesives for IC tags

Adhesives for copper clad laminates

Target stock: XP,H

Dielectric properties

| H-100 | XP11B | ||

|---|---|---|---|

| Relative permittivity (dielectric constant) |

2.45 GHz | 2.4 | 2.2 |

| 10 GHz | 2.1 | 2.2 | |

| Dielectric loss tangent | 2.45 GHz | 0.0006 | 0.0004 |

| 10 GHz | 0.0006 | 0.0004 | |

Dielectric properties of UNISTOLE™ coating (100µm) measured by cavity resonator perturbation method.

Compliance with food laws and regulations

We offer a lineup of grades that comply with food laws and regulations.

*Please contact a representative to inquire about the status of inclusion in specific laws and regulations.

*Click here for Food Regulation Listing Status.

Main applications

Heat sealing materials for PTP packaging

Heat sealing materials for food packaging

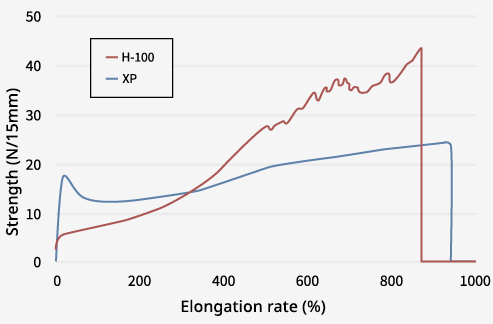

Stretchability (extensibility)

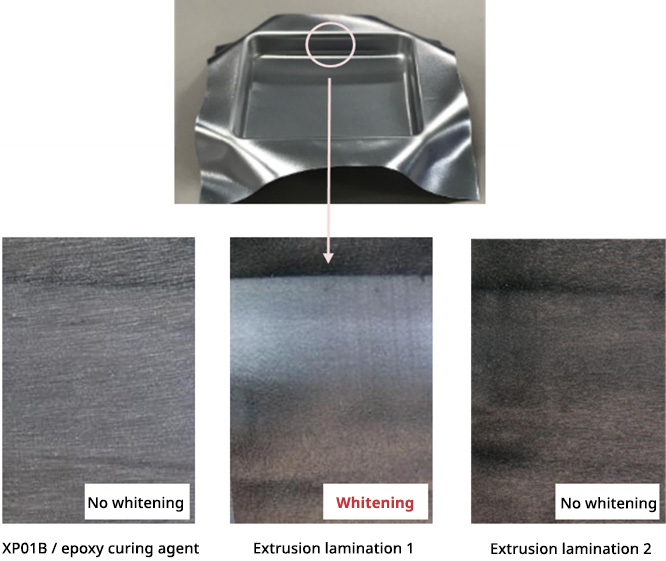

UNISTOLE™ has superior stretchability compared to PP and PE. It can also be added to PP and PE dispersions to improve whitening during molding.

Main applications

Heat seal coatings for decorative films

Dry laminate adhesives for Lib (lithium-ion battery) pouches

Target stock: XP,H

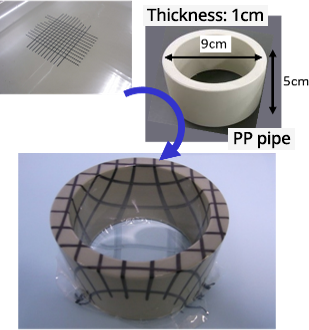

Stretchability during TOM molding

[Molding example]

Prototype film

Acrylic film (75µm) / adhesive layer (40µm)

Formed film temperature 140℃, substrate preheating 100℃

Pressure 300kPa, pressurization time 5s

No peeling of the substrate was observed, even at the most stretched point (approx. 500% stretching)

Stretchability of coating film

UNISTOLE™ coating (130µm) peeled at room temperature, 180℃, 100mm/min.

Improvement of whitening during cold forming

UNISTOLE™ is applied as a coating on soft aluminum and dried.

(Drying conditions: 120°C for 30 seconds. Dry film thickness: 4 μm).

The sample is hand-laminated with CPP at the prescribed temperature and cured at 60°C for 3 days.

The laminated sample is deep-drawn at a depth of 5 mm, and the circled part is observed under an optical microscope (x20 magnification).

*Please inquire separately about hardener.

Liquid repellency

Coating with UNISTOLE™ can grant water repellency to the substrate surface. Coated surfaces can also be heat-sealed to each other.

Main applications

Liquid-repellent heat seal coatings for aluminium, paper, and PP

Target stock: XP,R

Liquid repellency by grade

| Liquid | Liquid repellency | |

|---|---|---|

| Soft AL substrate material | Paper substrate | |

| Water | ◎ | ◎ |

| Yogurt | ○ | - |

| Black coffee | ◎ | ◎ |

| Milk coffee | ○ | ○ |

| Milk | △ | △ |

| Cooking oil | × | × |

| Ketchup | × | × |

| Mayonnaise | × | × |

UNISTOLE™ (XP04A / R-200X=5/16) is applied as a coating on a soft aluminium / paper substrate and dried. (Drying conditions: 80℃ for 60 seconds. Dry film thickness: 2 μm).

Drops of the prescribed liquid are dropped onto the substrate and the droplets are observed. Assessment ratings are as follows.

◎: Drops slide on a flat surface when applied

○: Drops roll when the surface is tilted

△: Drops do not roll when the surface is tilted.

×: Drops do not fall even when the surface is turned upside down

Transparency

Highly transparent adhesive layers can be formed by thin coating.

Main applications

High-transparency adhesives

Target stock: H

High transparency

UNISTOLE™ (H-200) is applied as a coating on glass and dried. (Drying conditions: 120℃ for 30 seconds. Dry film thickness: 5 μm).

Transparency by grade

| Grade | Haze |

|---|---|

| H-200 | 0.1 |

| XP01B | 13.3 |

| XP10B | 17.8 |

| XP04A | 33.8 |

UNISTOLE™ is applied as a coating on glass and dried. (Drying conditions: 120℃ for 30 seconds. Dry film thickness: 5 μm).

Glass substrate haze: 0.1