Contributing to Sustainable Packaging with

High Performance Water-Based Heat Seal Coatings

The reduction of single-use plastics is required to create a sustainable society.

As an alternative to plastic, carbon-neutral recyclable paper is gaining attention as a packaging material.

CHEMIPEARL™ can provide functions such as heat sealing and water / oil resistance to paper, and contribute to the conversion of plastic packaging to paper.

Application

-

Butter wrapping packaging

AL/Heat seal coating/Paper

Heat seal coating

(oil resistance) -

Chocolate packaging

AL/Heat seal coating -

Paper containers

Paper/Heat seal coating -

Secondary packaging

Paper/Heat seal coating

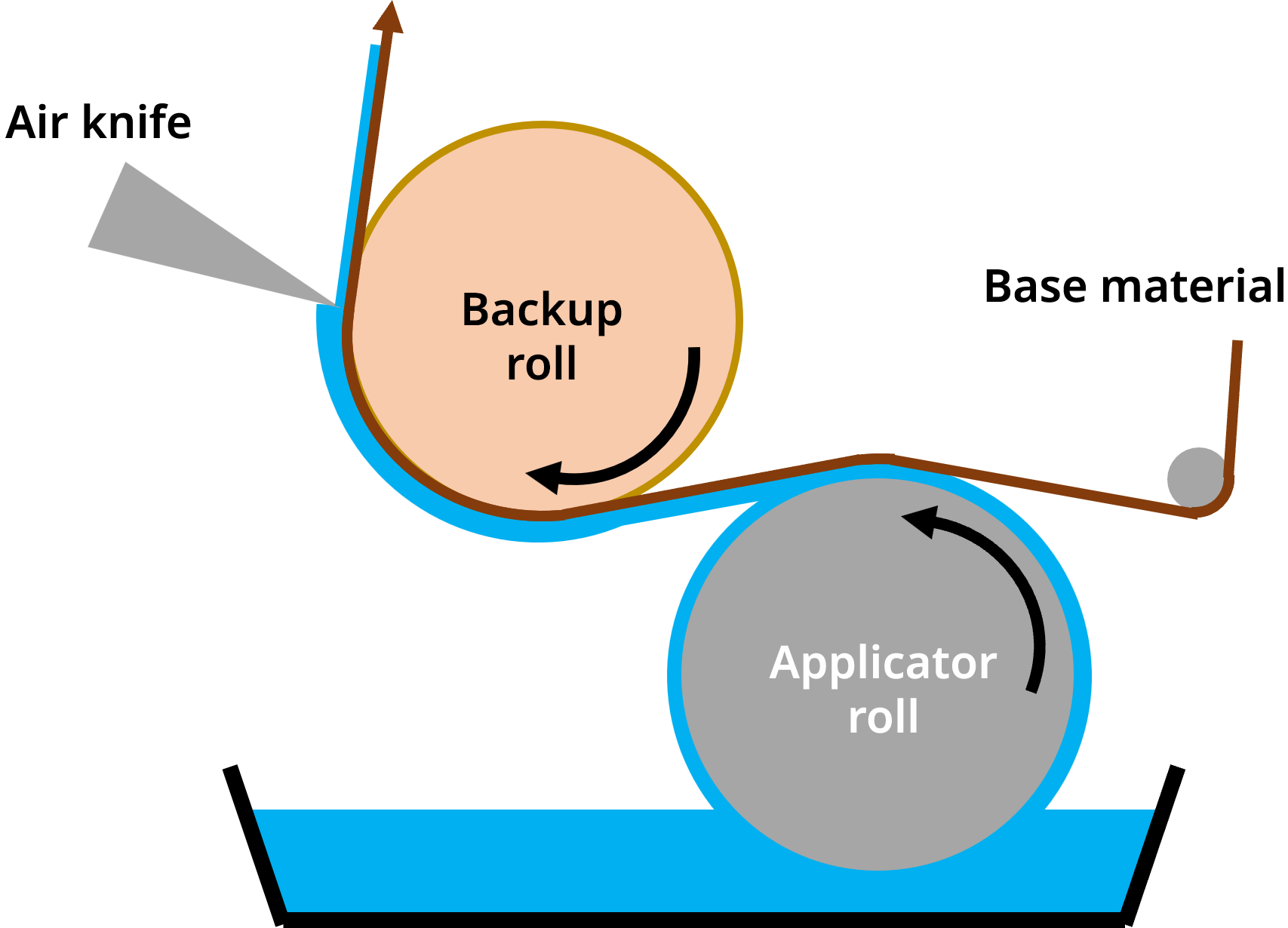

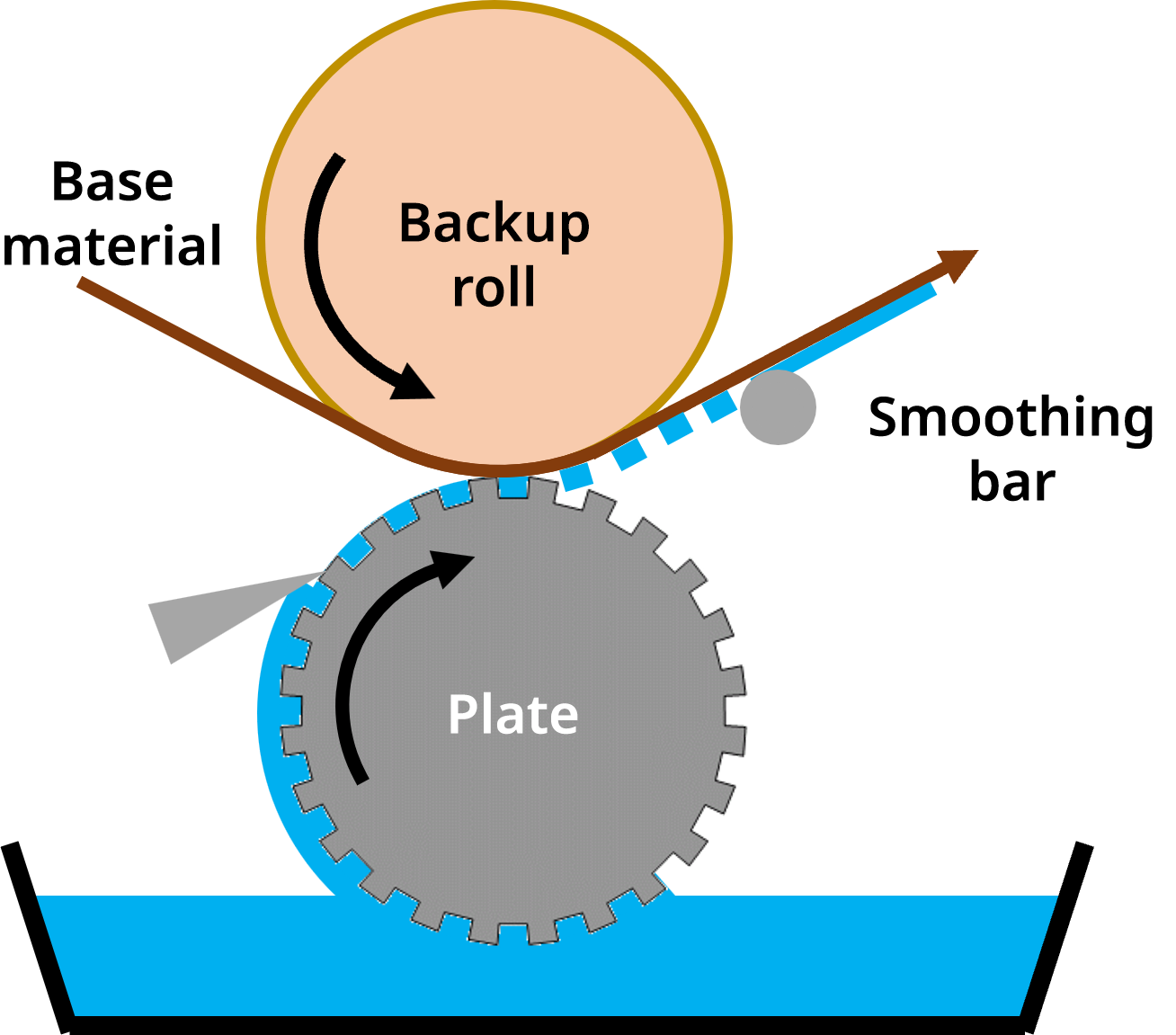

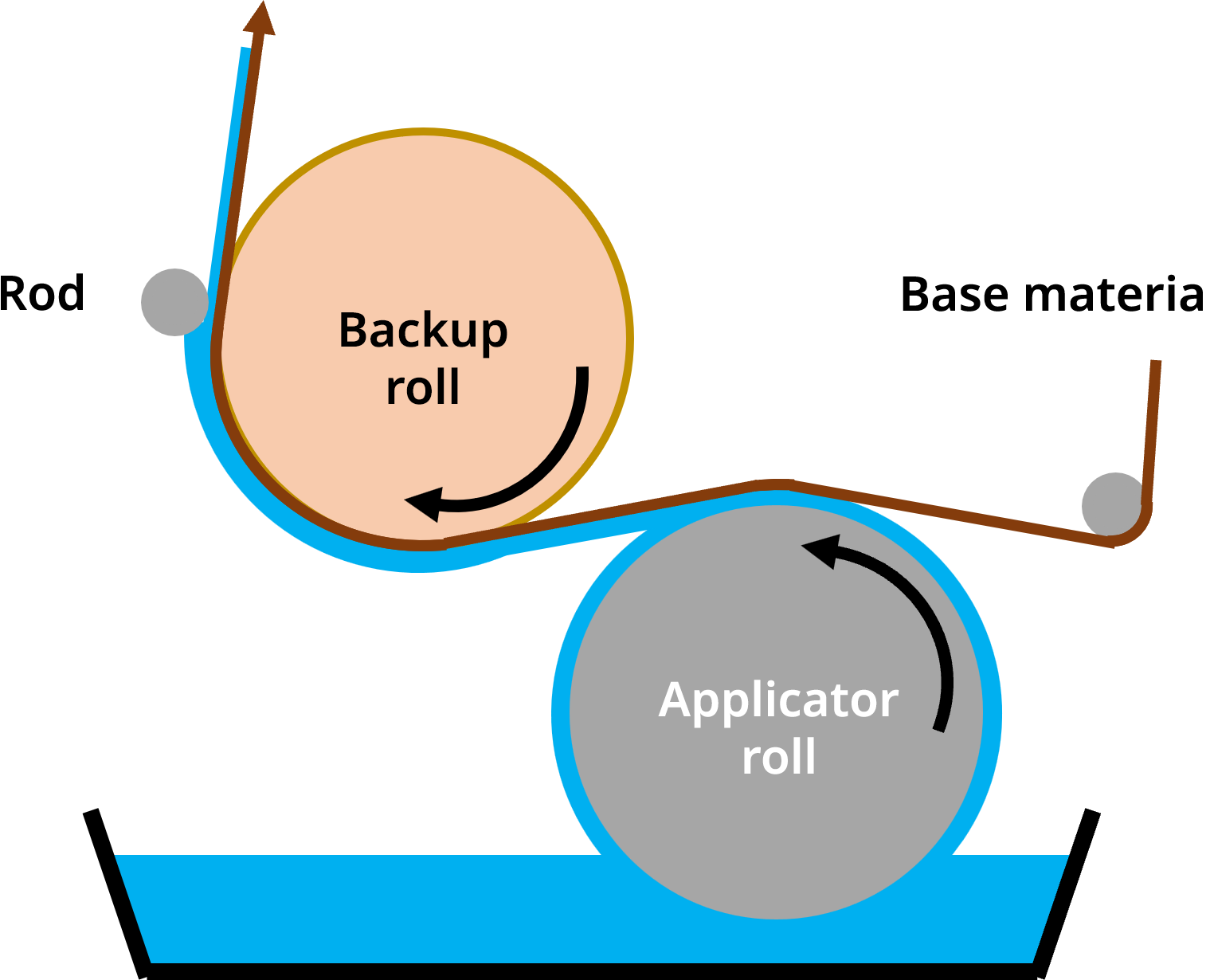

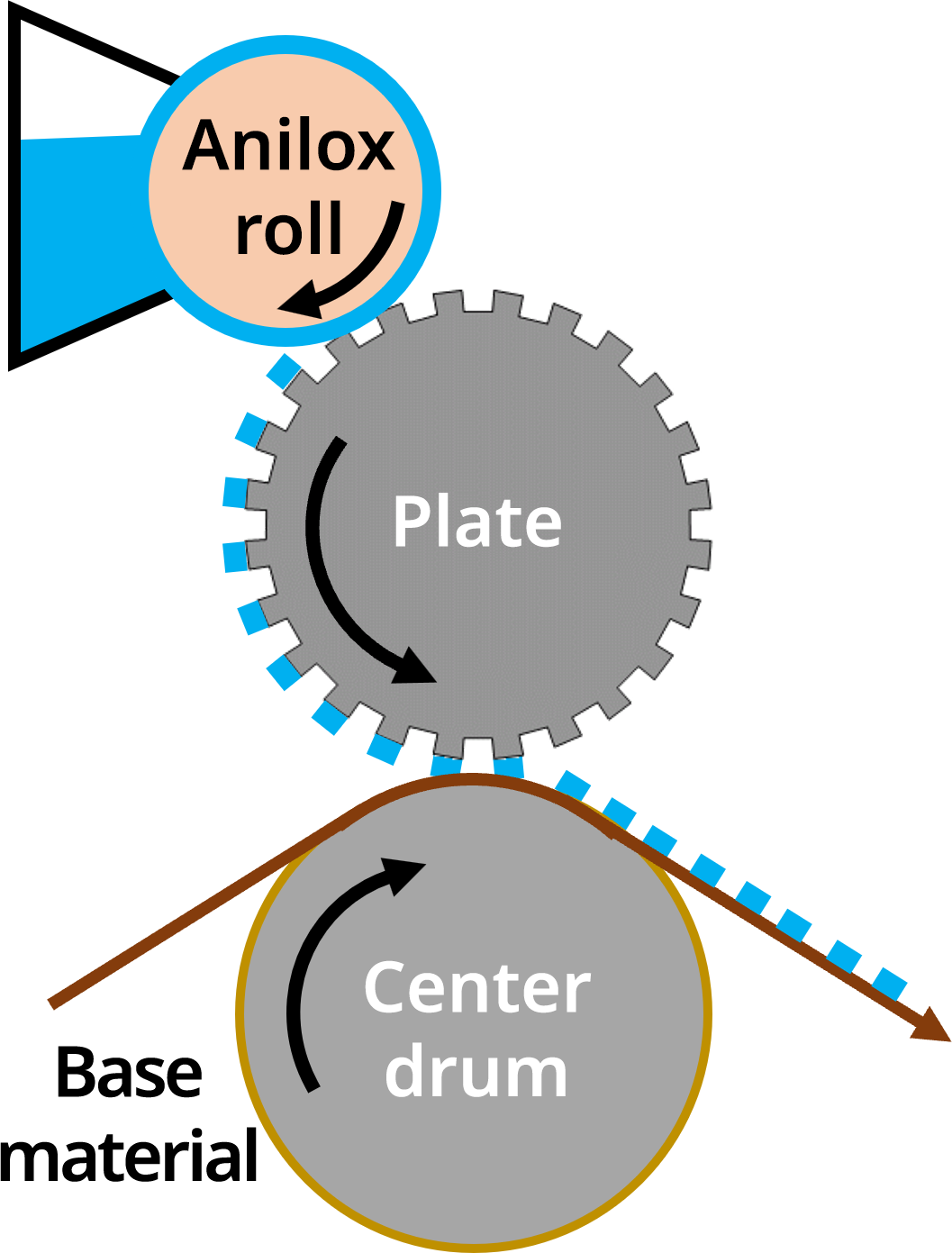

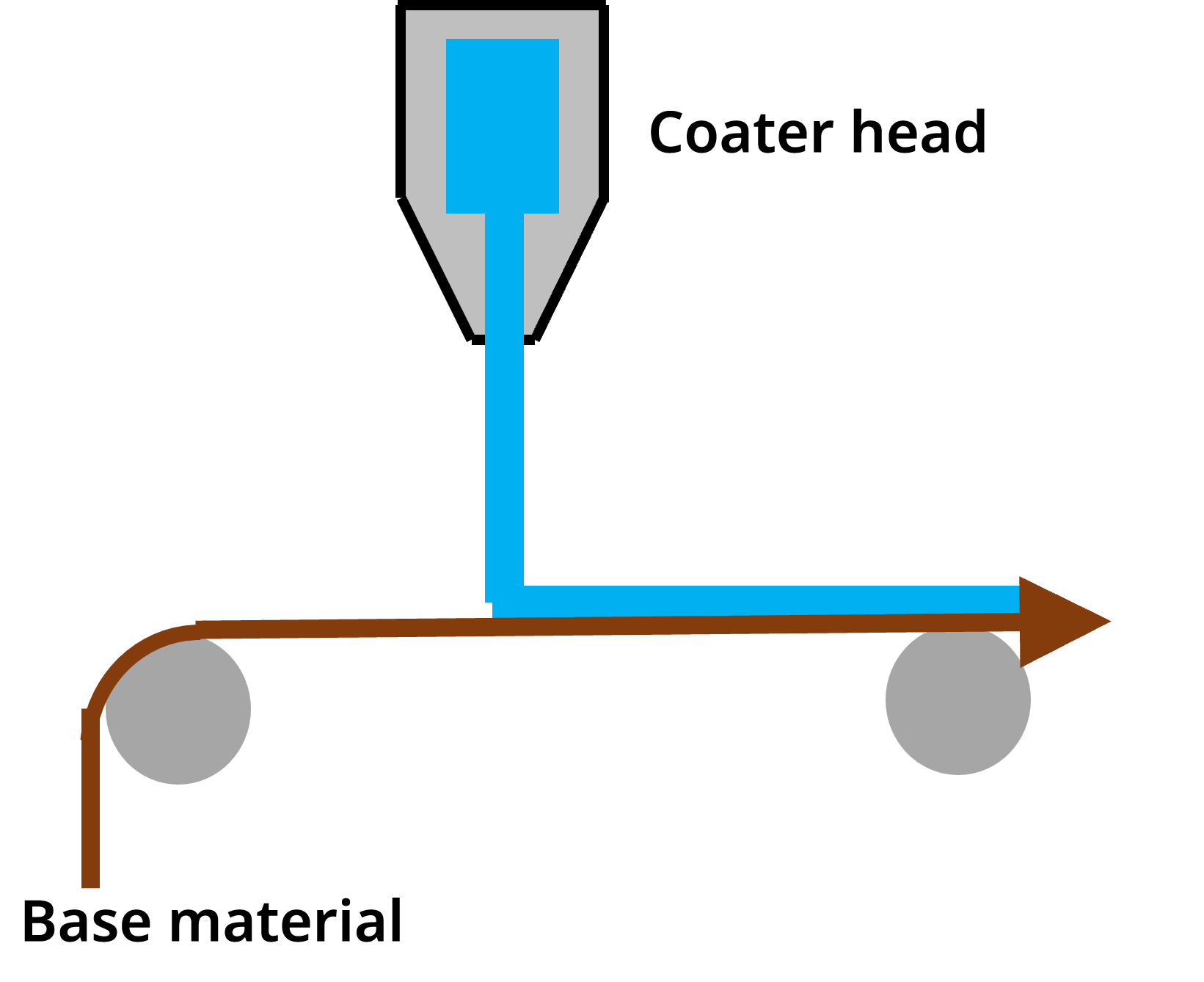

Coating Methods

-

Air knife coater

-

Gravure coater

-

Rod coater

-

Flexographic printing press

-

Curtain coater

High-speed Production Line Suitability

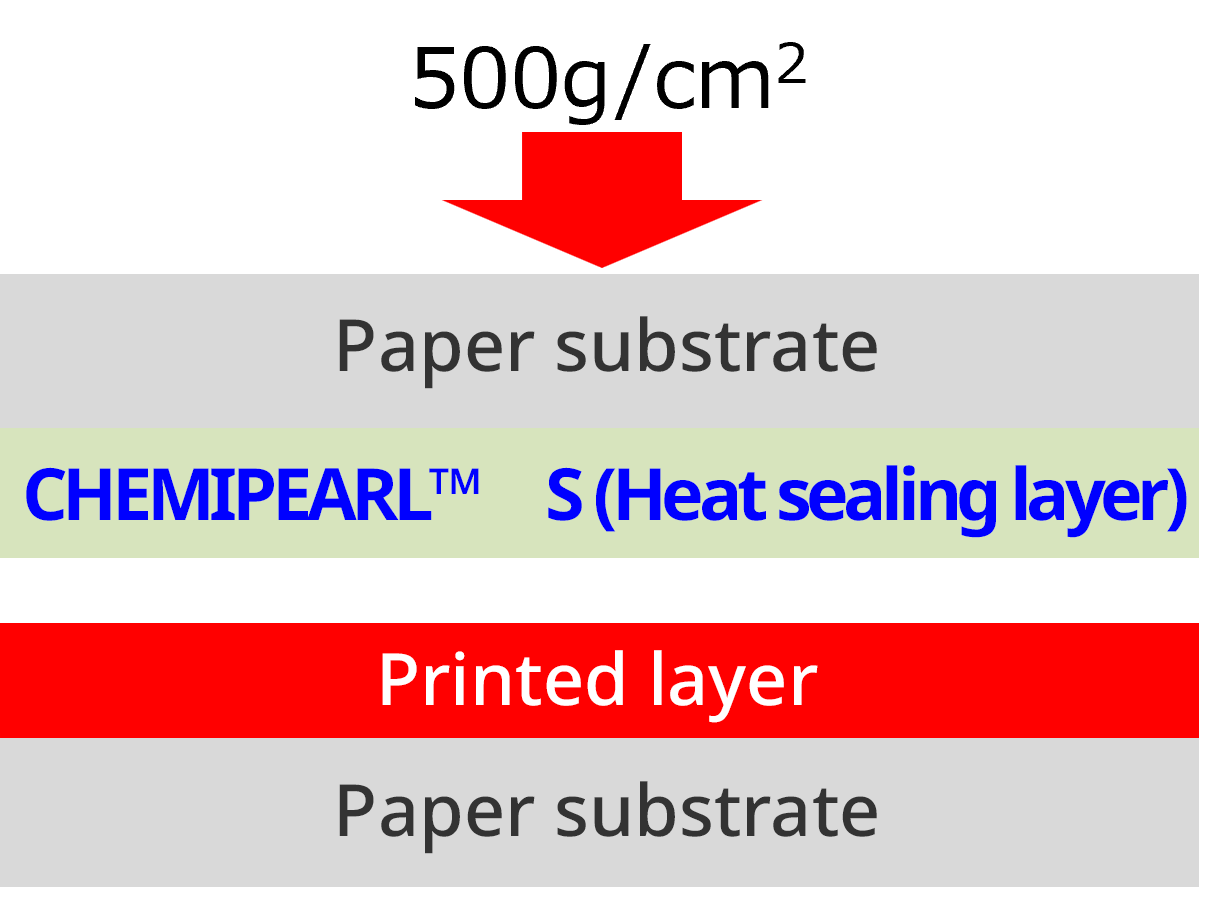

CHEMIPEARL™ S Series Anti-blocking Performance

Test conditions

Paper substrate: 80gsm single-side gloss base paper

Coating amount: 5-6g/m²

Load: 500g/m²

Storage conditions:

60℃×65%RH×20Hr

-

No ink transfer

CHEMIPEARL™ S -

Acrylic resin-based -

EAA resin-based

Recyclability

Recyclability assessment of CHEMIPEARL™ coated paper

CHEMIPEARL™ coated paper (paper 390gsm / coated layer 6gsm) and commercially available PE-laminated paper cup were impregnated with water overnight, and mixed by 2L pulper for 15 minutes.

Biodegradability

Compostability assessment of CHEMIPEARL™ coated paper

Composition of CHEMIPEARL™ coated paper cups

Paper 190gsm/ coating layer 6gsm + 3gsm

It certifies that packages or products are compostable

in an industrial composting plant.

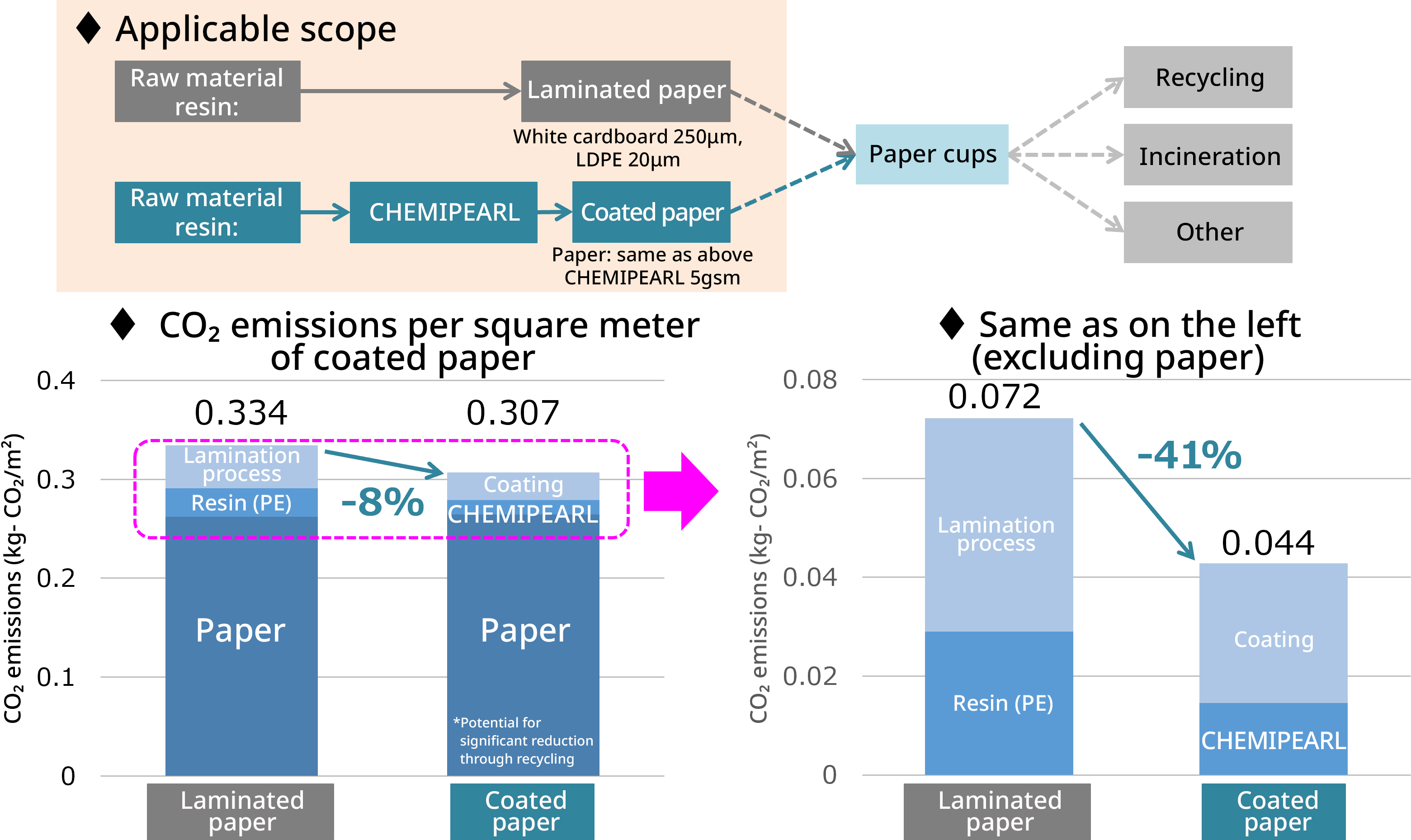

Reduction of Plastics

Carbon footprint assessment

<Mitsui Chemicals estimate>

LDPE: 1.53 kgCO2/kg (B-JP310001)

CHEMIPEARL™: 2.44 kgCO2/kg (MCI)

Extrusion process GHG: 0.043kgCO2/m²

Coating process GHG: 0.028kgCO2/m²

CO2 emission factor: 0.334 kg-CO2/kwh (2018 Kanden)

CO2 conversion factor for the above: 0.241 kg-CO2/kg (MCI)

CO2 conversion factor for water: 0.118 kg-CO2/㎥ (MCI)